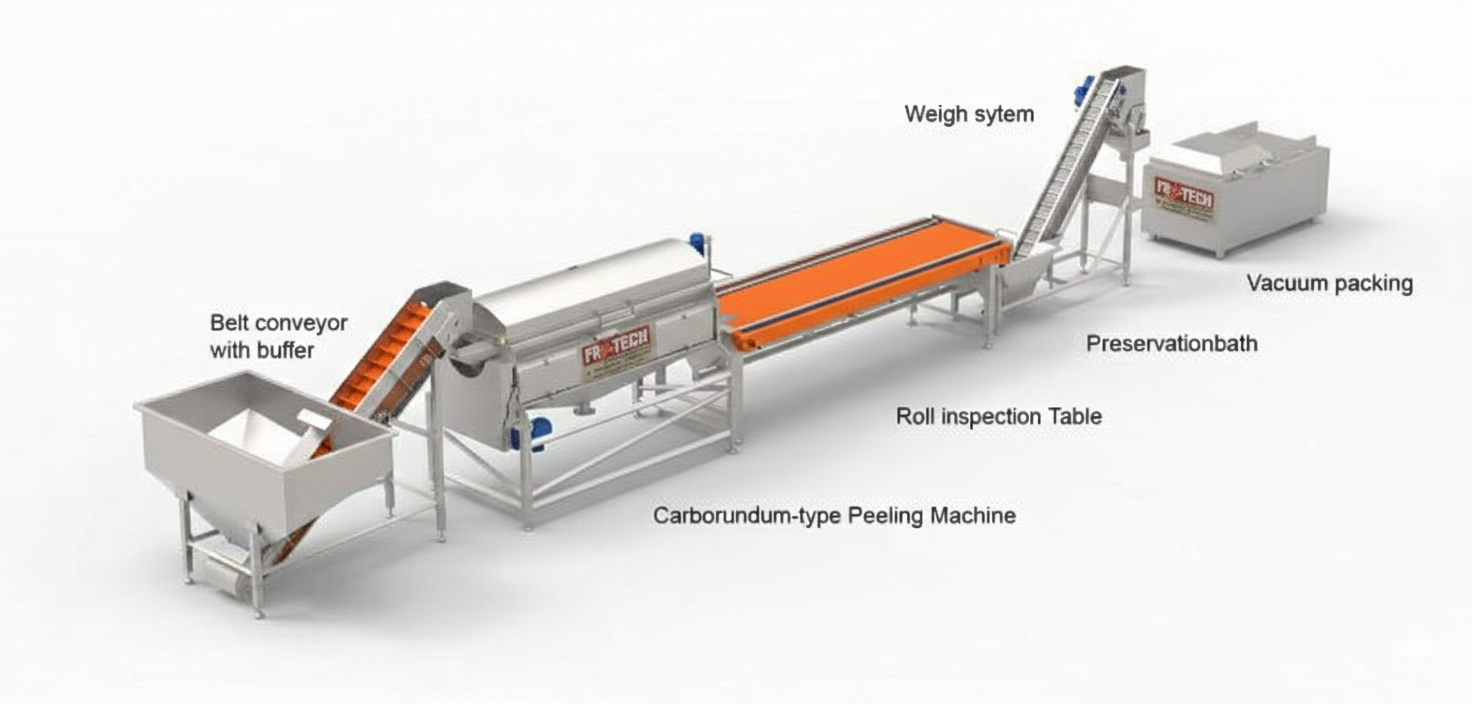

Vegetable Washer Peeling and Packing Machine

For a processing capacity of 100 to 1,000 kg per hour, you are moving

from small-scale machines to a Semi-Automatic or Fully Automatic Processing

Line. In this scale, the machines are usually connected by conveyors to form a

continuous flow.1

1. Vegetable Washing Machine (Bubble & Spray Type)

At 1,000 kg/hr, a simple tank won't work. You need a Continuous Bubble

Washer.

- Mechanism:

Uses a high-pressure air blower to create bubbles in the water, which

gently "scrubs" the vegetables (like tomatoes, leafy greens, or

peppers) without damaging them.

- Ozone Integration: Often equipped with an Ozone Generator to kill 99.9 % of bacteria and remove pesticide residues—essential for "Ready-to-Eat" exports.

2. Vegetable Peeling Machine (Roller Brush Type)

For root vegetables like potatoes, carrots, ginger, and beetroot.

- Mechanism:

Features 7 to 9 long Nylon Brush Rollers (soft for washing, hard/abrasive

for peeling). As the rollers spin, water jets wash away the

skin.

- Capacity: 300 kg to 1,000 kg per hour.

3. Packing Machine (Vacuum or Flow Wrap)

Depending on your end product (whole vegetables or cut/peeled), you need

one of these:

- Vacuum

Packing Machine (For Peeled/Cut Veg): Best for extending shelf life.

- Capacity:

1,000 pouches per hour.