Potato Flakes Machine

Fully Automatic Potato Flakes Machine is a comprehensive production line

that converts raw potatoes into dehydrated, shelf-stable flakes.1 Unlike

potato chips (which are fried slices), flakes are made by cooking, mashing, and

drum-drying the potato.

Since your business focuses on a hybrid of in-house fabrication and

branded components, this project allows you to manufacture the heavy-duty

stainless steel tanks and conveyors while integrating specialized European or

high-end Indian technology for the drum and sensors.

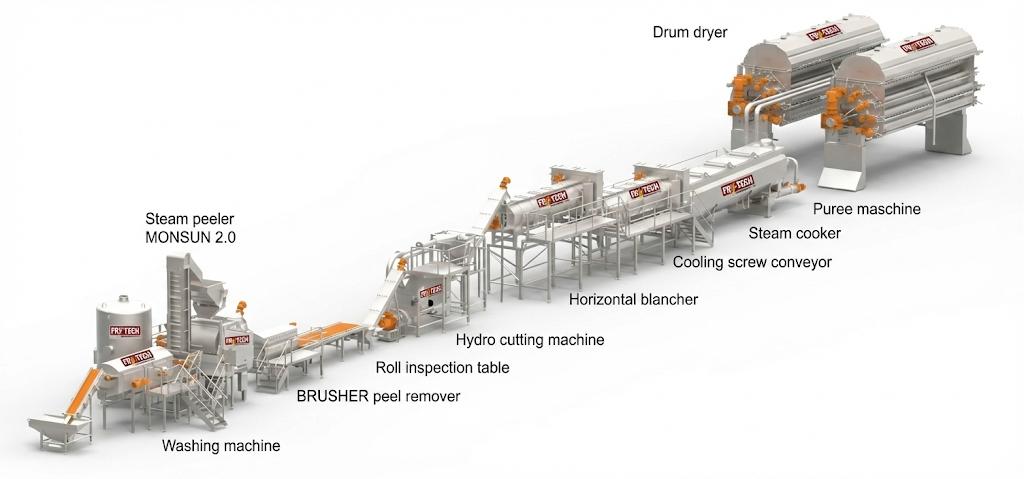

1. The Fully Automatic Process Flow

A complete line is divided into three main sections:

Section A: Preparation (The "Wet" End)

- Destoner &

Washer: Removes stones, mud, and debris using water flotation.

- Peeler (Steam or

Abrasive): Removes skins with minimal flesh loss.

- Slicer/Cutter: Cuts

potatoes into uniform slices (approx.5 15mm) to ensure even

cooking.

- Blancher:

Pre-cooks the slices to gelatinize starch and maintain color.

- Cooler: Uses cold

water to "retrograde" the starch, which prevents the final

flakes from being too sticky.

Section B: Processing & Drying (The "Core")

- Steam Cooker:

Final cooking until the potatoes are soft enough to mash.

- Ricer/Masher:

Converts cooked slices into a smooth, lump-free mash.

- Additive Dosing:

Automatically mixes in emulsifiers (like monoglycerides) to improve

texture.

- Drum Dryer (The

Heart): The mash is spread onto a massive, steam-heated rotating drum. It

dries into a paper-thin sheet in seconds.

- Scraper (Doctor

Blade): Continuously scrapes the dry sheet off the drum.

Section C: Finishing (The "Dry" End)

- Flake

Mill/Sifter: Breaks the large dried sheets into uniform 5–6 mm flakes.

- Air Transport:

Uses a pneumatic system to cool the flakes and move them to storage.

- Automatic

Packing: Weighs and seals the flakes into moisture-proof bags (usually

25kg bags for industrial use).

2. Technical Capabilities

|

Feature |

Standard Automatic Spec |

|

Capacity |

500 kg/hr to 1,500 kg/hr (finished product) |

|

Raw Material Ratio |

Approx. 6 kg of potatoes = 1 kg of flakes |

|

Material |

All contact parts in SS 304 or SS 316 |

|

Control System |

PLC-based (Siemens/Schneider) with HMI Touchscreen |

|

Heating |

High-pressure Steam (Boiler required) |

3. Your Hybrid Manufacturing Strategy

- Fabricate

In-House: * Screw Conveyors, Elevators, and Inspection Tables.

- Blanching

and Cooling Tanks.

- Structural

Frames and Air-Ducting systems.

- Source Branded

Items:

- Drum

Dryer: Source a high-precision, pressure-certified drum (ASME certified).

- Steam

Peeler: Integration with brands like Tomra or Kiremko for high-yield

peeling.

- Automation:

Schneider or ABB switchgear and PLC logic.

4. Why This is a Great Offer for Your Clients

- Waste

Utilization: Your clients can use "B-grade" potatoes or rejects

from French fry lines to make high-value flakes.

- Multi-Purpose End

Product: Flakes are sold to snack manufacturers (for Pringles-style

chips), bakeries, and the instant-mash industry.

- Efficiency: A

fully automatic line reduces labour from 15 people to just 2–3 operators.