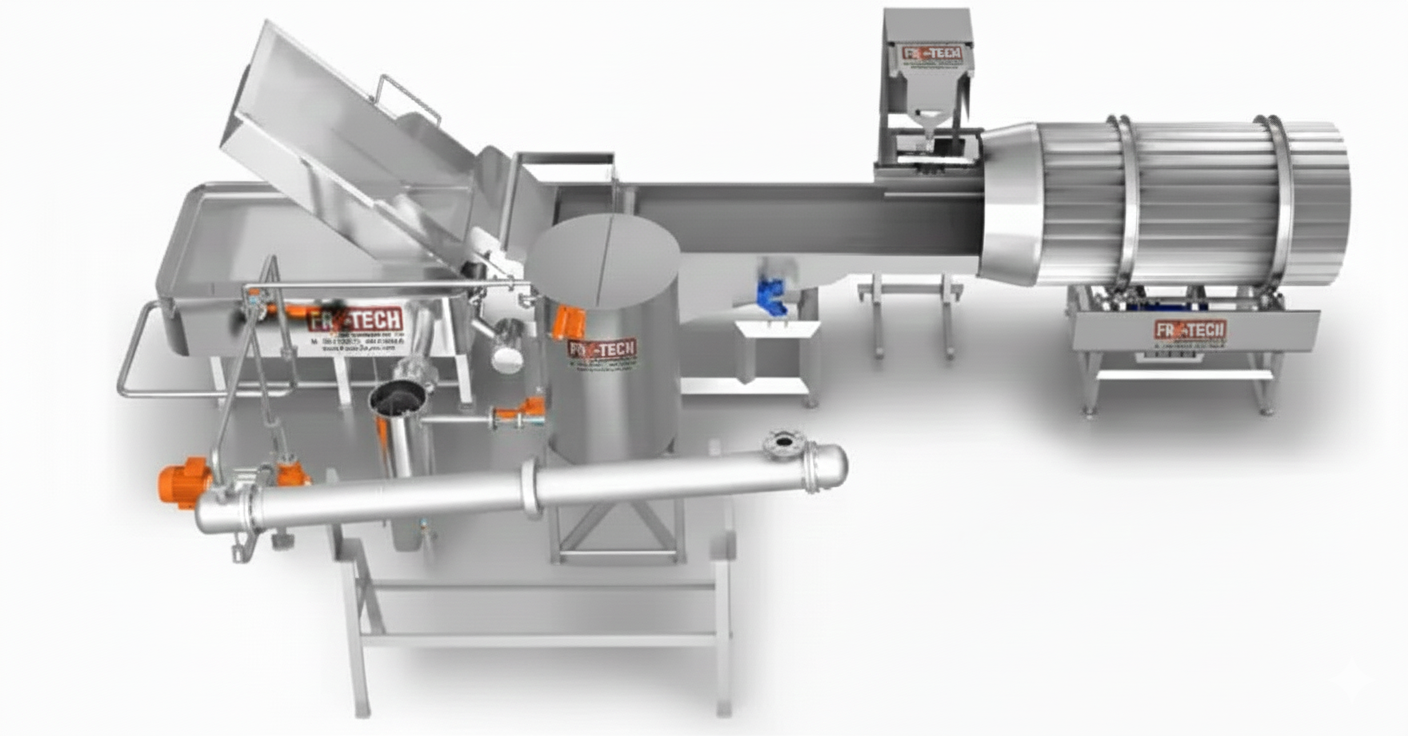

Batch Type Frying Machine (Thermal Fluid Base)

Thermal Fluid Base

Batch Fryer

Unlike traditional

fryers where a flame hits the pan, here a separate "Thermic Fluid

Heater" (Boiler) heats a special mineral oil to0200°C which then circulates through a heat exchanger submerged in your cooking oil.3

|

Feature |

Details |

|

Heating Method |

Indirect (Thermal

oil coil inside the frying tank) |

|

Oil Life |

3x longer than

direct fire (No hot spots, low FFA) |

|

Temperature

Control |

Precise PLC-based |

|

Pan Shape |

Rectangular |

|

Safety |

Zero risk of oil

catching fire from a burner flame |

2. The Vibro

De-Oiler (Vibratory Screen)

Once the batch is

lifted from the fryer, it drops onto the Vibro Screen. This is the bridge

between frying and flavoring.

- Function: It uses high-frequency,

low-amplitude vibrations to "shake off" excess surface oil from

the namkeen or chips.

- Oil Recovery: The recovered oil is

collected in a tray and can be pumped back into the fryer, saving costs.

- Cooling: It partially cools the product so

that the spices in the next stage don't "burn" or clump due to

excessive heat.

3. Flavoring Drum

(Seasoning System)

The de-oiled

product moves into the Flavoring Drum (also known as a Coating Pan or Seasoning

Drum).

- Continuous Rotation: The drum is tilted

and rotates slowly to toss the snacks.

- Spice Application: A screw-type powder

feeder or a liquid spray system applies the masala uniformly.

- Internal Flights: Specially designed

baffles (fins) inside the drum ensure that every piece is coated without

breakage.

4. Technical

Specifications (Integrated Line)

|

Component |

Typical Specs

for 150–200 kg/hr Line |

|

Thermic Fluid

Heater |

1 Lakh to 2 Lakh

kcal/hr capacity |

|

Frying Pan

Material |

SS 304 (Food

Grade) |

|

Vibro Motor |

0.5 HP (Dual

Unbalanced Motors) |

|

Flavoring Drum |

6 to 8 feet long,

2.5 feet diameter |

|

Total Power Load |

5 HP to 8 HP

(Motors) + Heater Load |

5. Key Advantages

of this Integrated Line

- Uniformity: Every batch has the exact same

color, crunch, and spice level.

- Labor Saving: The product moves

automatically from the fryer to the flavoring drum, reducing the need for

manual handling.

- Fuel Efficiency: A 3-pass thermal fluid

heater can save up to 25% in fuel compared to direct-fired diesel fryers.

- Hygienic: The indirect heating eliminates smoke and carbon soot from the production area.