Pellet Snacks Production Line Fryer Machine

₹ 24,00,000.00/-

Product Details:

| Minimum Order Quantity | 1 Piece |

| Capacity | 500 kg/hr |

| Automation Grade | Automatic |

| Heating Type | Wood Fired |

| Application | 2D Pellets, Pasta Pellets, Multigrain Pellets, Potato Pellets, 3D Pellets |

| Machine Type | Semi Automatic, Automatic |

| Country of Origin | Made in India |

| For More Info | Kindly Connect |

Snack Pellet Frying Line: Integrated System for Expanded Snacks

The Snack Pellet Frying Line is a fully integrated, automated processing system designed for the continuous, high-volume production of popular ready-to-eat expanded snacks. These products, such as various extruded shapes (2D or 3D), are made from raw pellets (often based on corn, wheat, potato, or rice flour) which expand significantly when fried. The line is engineered for high efficiency, quality consistency, and rigorous control over the frying process.

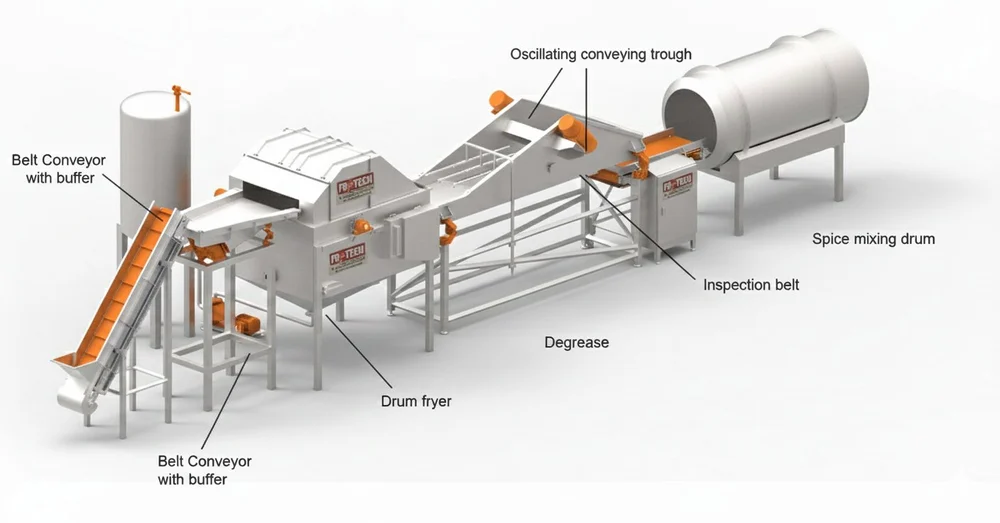

Components and Operational Stages

The typical Snack Pellet Frying Line comprises several interconnected and highly specialized units:

- Continuous Feeder/Hopper: Ensures a smooth, regulated flow of raw, dried snack pellets into the frying system, maintaining consistent product density within the fryer.

1. Continuous Frying System (Frying Tunnel):

Indirect Heating: Often utilizes an Indirect Heating System (Thermic Fluid Heater) where hot oil flows through tubes within the fryer, providing gentle, controlled heat transfer. This prevents oil burning, extends oil life, and maintains highly stable frying temperatures.

Submerged Conveyance: Uses perforated belts to carry the pellets through the oil. The system ensures the pellets are fully submerged to achieve uniform expansion and color.

Continuous Oil Filtration System: Immediately and continuously removes small crumbs and debris generated during expansion. This is critical for controlling the Total Polar Compounds (TPC) in the oil.

Oil Extraction/De-oiling Unit: A specialized conveyor or vibratory unit that gently shakes off excess surface oil from the hot, finished snacks immediately after they exit the fryer.

Seasoning System (Tumbler/Flavoring Drum): The de-oiled product is transferred to a rotating drum where flavorings (powder, slurry, or oil-based) are uniformly applied.

Cooling Conveyor: Reduces the temperature of the flavored snacks to ambient levels before packaging, ensuring the product retains crispness and preventing moisture buildup inside the final sealed package.

2. Superior Oil Management and Cost Control:

The use of an Indirect Heating System is the most critical cost-saving feature. By eliminating direct contact between the heating elements and the oil, the system prevents localized scorching, dramatically slowing down the degradation of the frying medium. Coupled with continuous filtration, this approach substantially extends the frying oil's lifespan, providing major savings on oil procurement and disposal—often the highest variable cost in snack production.

3. High Throughput and Reduced Labor Requirement:

This is a fully continuous operation, meaning raw pellets are continuously fed and finished, seasoned snacks are continuously discharged. This high-efficiency mechanism translates to thousands of kilograms of product manufactured per shift, maximizing overall plant output. The integration of all stages, from frying to seasoning and cooling, drastically reduces manual labor reliance, minimizing labor costs and the risk of product handling contamination.

4. Flavor and Quality Retention:

The final integrated stages—de-oiling and uniform seasoning—ensure the final product is not overly greasy and that the flavor is evenly distributed. The cooling conveyor is crucial for preserving quality by rapidly bringing the product temperature down, preventing "after-browning" and locking in the desired crispness before packaging.

Additional Information:

- Item Code: FRY-TECH2D3DFRYER500

- Production Capacity: 500 Kg/Hr

- Delivery Time: 30 DAYS

- Packaging Details: Wooden