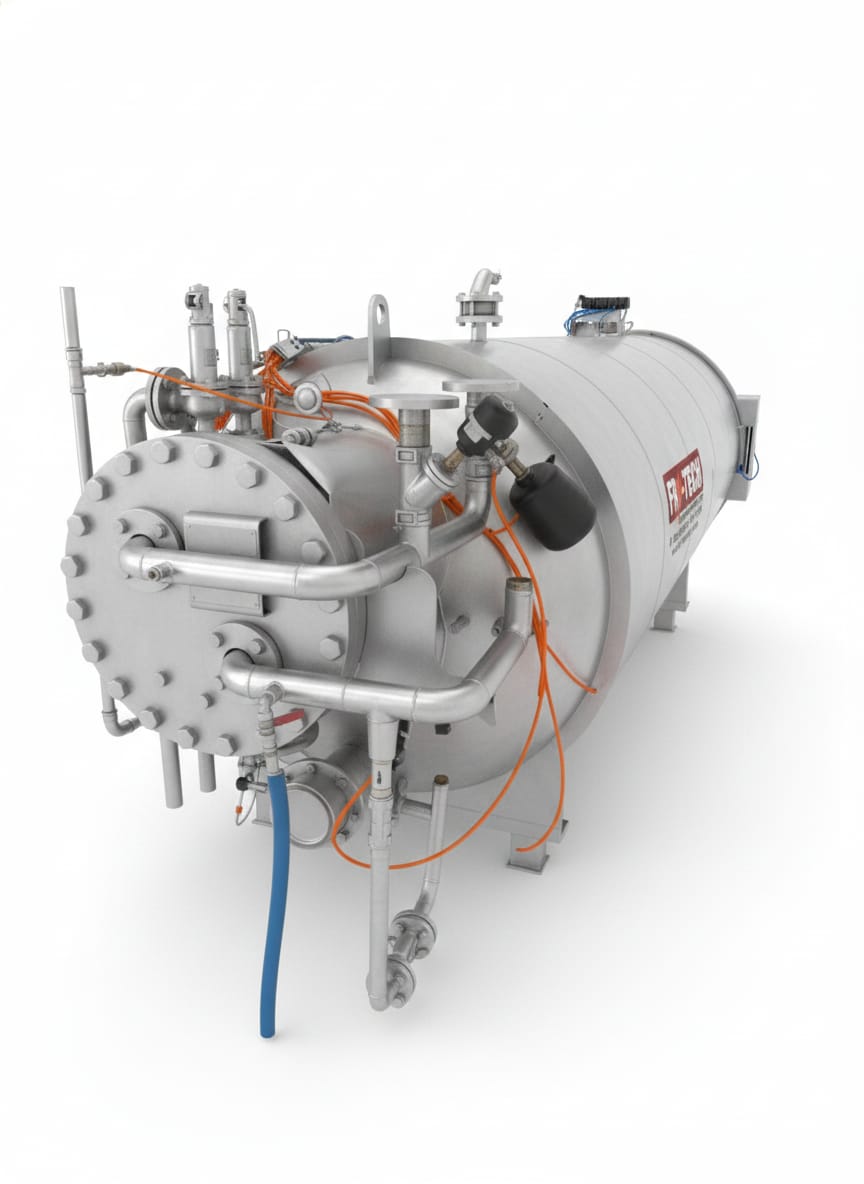

Horizontal Blancheur Machine

In industrial food processing, a Horizontal Blancher is a continuous

machine used to briefly treat products like vegetables, fruits, and potatoes

with hot water or steam. This process deactivates enzymes (stopping browning),

preserves color, and softens the texture before frying or freezing.

The Fry-Tech has split into two main horizontal designs: Belt Type and Screw/Auger

Type.

1. Types of Horizontal Blanchers

A. Horizontal Belt Blancher

Ideal for delicate products (like French fries, green peas, or leafy

greens) that might break if tumbled.

- Mechanism: A

stainless steel mesh belt carries the product through a hot water bath or

under steam sprays.

- Key Advantage:

Very gentle handling; "Dual-mode" (immersion or spray) options

are common.

- Common Use:

Large-scale potato chip and French fry lines.

B. Horizontal Screw (Auger) Blancher

Ideal for small, sturdy products (like diced carrots, chickpeas, or

kernels).

- Mechanism: A

large internal screw (auger) slowly rotates inside a perforated drum,

pushing the product forward through the hot water.

- Key Advantage:

More compact footprint than belt blanchers and ensures every single piece

is submerged for a precise "dwell time."

- Common Use: Root

vegetables and pulse processing.

2. Technical Specifications (2026 Standards)

|

Feature |

Standard Industrial Specification |

|

Material |

SS 304 (Standard) or SS 316 (for acidic/salty

products). |

|

Heating Source |

Direct Steam Injection or Electric Heaters. |

|

Temperature Control |

PLC-based automatic PID controllers (Range: 70°C to

100°C). |

|

Speed Control |

Variable Frequency Drive (VFD) to adjust blanching

time (2–20 mins). |

|

Cleaning |

"Clean-In-Place" (CIP) systems with

liftable hoods for easy sanitation. |

4. Key Factors to Consider

- Water

Circulation: Ensure the machine has a centrifugal pump and a

"side-stream" filter to remove starch and debris, which keeps

the water clean longer.

- Insulation:

Modern 2026 models feature double-walled insulation to reduce heat loss by

up to 30%, significantly lowering your energy bills.

- Cooling Section:

Most horizontal blanchers should be followed immediately by a Cooling

Conveyor or "Chiller" to stop the cooking process; otherwise,

the product will become mushy.

.jpeg)