French Fries Fryer Machine

Fully Automatic French Fries Production Line (500 to 2000 kg/hr), the

system is an end-to-end industrial plant that converts raw potatoes into

finished, frozen (or fresh) fries.

At the 2,000 kg/hr (2 Ton) scale, the line typically requires a

specialized External Heat Exchanger system to maintain the high thermal energy

needed for such a massive volume of product.

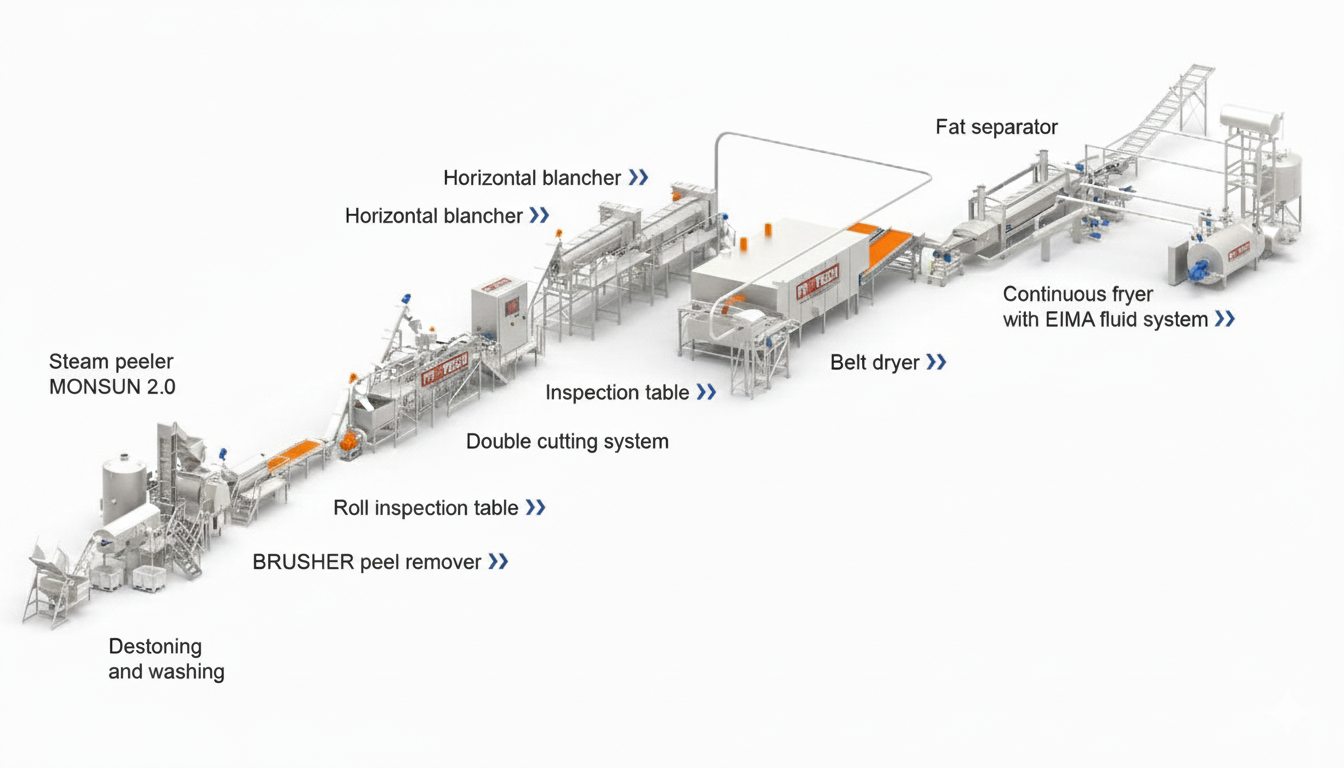

1. Complete Production Line Components

A fully automated industrial line consists of these specific stages:

- Lifting

& Feeding: Bulk hopper with a screw/belt elevator.

- Washing

& Peeling: Continuous abrasive brush rollers or steam peeling.

- Picking/Sorting:

A conveyor where manual or optical sorters remove defective potatoes.

- Cutting:

High-speed centrifugal hydro-cutting or mechanical strip cutters (7x7mm to

12x12mm).

- Rinsing

& Grading: Removes surface starch to prevent sticking and sorts out

small "slivers."

- Continuous

Blanching: Hot water treatment to deactivate enzymes and preserve color.

- Drying/De-watering:

Vibratory screens followed by air-knife tunnels to remove surface

moisture.

- Continuous

Fryer: The "Multi-Zone" fryer with auto-residue scraping and oil

filtration.

- Vibratory

De-oiling: High-frequency vibration to remove excess oil.

- Pre-cooling

& IQF Freezing: A freezing tunnel (Individual Quick Freezing) that

brings temperature to -18C.

- Automatic

Packaging: Multi-head weighing and vertical form-fill-seal (VFFS) bagging.

2. Technical Specifications for 1000–2000 kg/hr

|

Feature |

Details |

|

Material |

Full SS 304 or SS 316L (Industrial Grade) |

|

Heating Source |

Thermic Fluid (Indirect) or Diesel/Gas Burners |

|

Total Power Load |

120 HP to 750 kW (depending on freezer and heater) |

|

Oil Management |

Continuous filtration with External Heat Exchanger |

|

Line Length |

60 feet to 150 feet (depending on IQF tunnel) |

|

Automation |

Full PLC Control with SCADA monitoring |

Note:- We are a hybrid manufacturing and equipment supply company. While we manufacture a core range of high-quality machinery in-house, we also collaborate with leading global brands to provide our clients with a complete, end-to-end production solution."

"A blend of In-house Engineering and Global Brands. We manufacture

specialized machines at our facility and source premium branded equipment to

ensure you get the best of both worlds."

Option 3: Focus on "Total Solutions" (Best for Sales

Proposals)