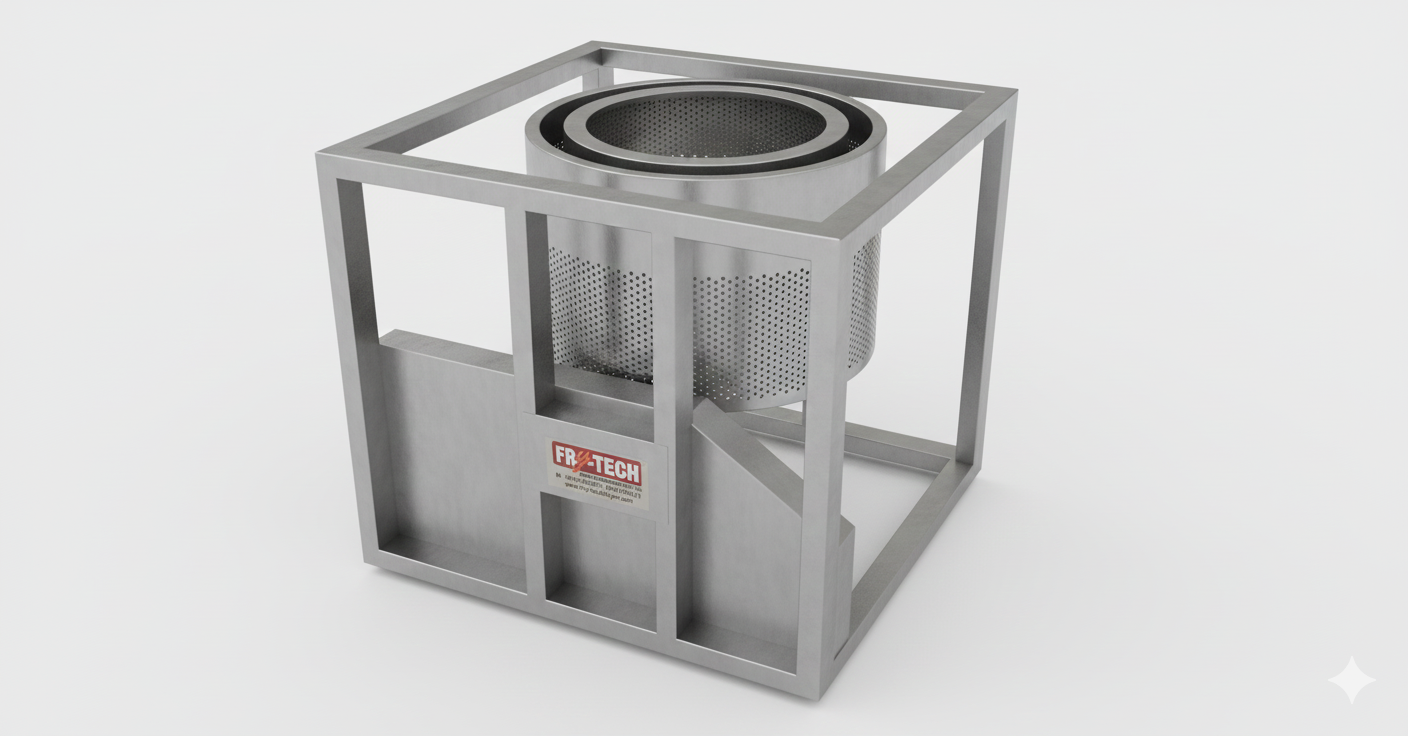

Tilting Hydro Machine

A Tilting Hydro

Machine (also known as a Centrifugal Deoiler or Hydro Extractor) is essential

for removing excess surface oil from fried snacks or surface water from washed

vegetables/potatoes.

In the snack

industry, this machine is the key to producing "non-greasy" chips and

namkeen. By removing excess oil, you not only improve the product's health

appeal and shelf life but also save significant costs by reusing the extracted

oil.

1. Technical

Specifications (Standard 10kg - 15kg Batch)

|

Feature |

Details |

|

Batch Capacity |

10 kg, 15 kg, 25

kg, or 50 kg |

|

Rotation Speed |

800 RPM to 1000

RPM |

|

Cycle Time |

30 seconds to 3

minutes (adjustable) |

|

Material |

Full SS 304

(Inner Basket & Outer Body) |

|

Motor Power |

1 HP to 3 HP

(Single or Three Phase) |

|

Automation |

Semi-Automatic

with Digital Timer |

|

Braking System |

Mechanical Foot

Brake or Electronic DC Brake |

2. Why the

"Tilting" Design is Important

Traditional hydro

machines are fixed, requiring the operator to manually scoop out the product

from the deep basket. The Tilting Mechanism offers:

- Effortless Unloading: Once the cycle

stops, the operator uses a hand lever or gear system to tilt the entire

basket upside down, dumping the product into a crate.

- Speed: It reduces downtime between

batches, allowing you to process 20–30% more product per hour.

- Hygiene: Minimal human contact with the

hot, processed food.

3. Key Features

& Components

- Centrifugal Basket: A high-speed rotating

inner drum with precision-drilled holes. The centrifugal force

"throws" the oil/water out of the snacks through these holes.

- Shock Absorption System: High-quality

machines use a "Three-Leg Suspension" or heavy-duty rubber

buffers to prevent the machine from "walking" or vibrating

excessively when the load is unbalanced.

- Oil Collection Outlet: A dedicated drain

pipe at the bottom that collects the extracted oil so it can be filtered

and returned to the fryer.

- Auto-Stop Timer: You can set the exact

time (e.g., 45 seconds for Potato Chips) so the machine stops

automatically, ensuring consistency across every batch.

4. Application in

Your Line

|

Process |

Function of

Hydro Machine |

|

Pre-Frying |

Removes surface

water from sliced potatoes after washing (reduces frying time and fuel). |

|

Post-Frying |

Removes 95% of

excess surface oil from Namkeen, Gathiya, or Chips. |

|

Vegetables |

Removes water

from leafy greens or chopped vegetables after washing for salads/frozen food. |