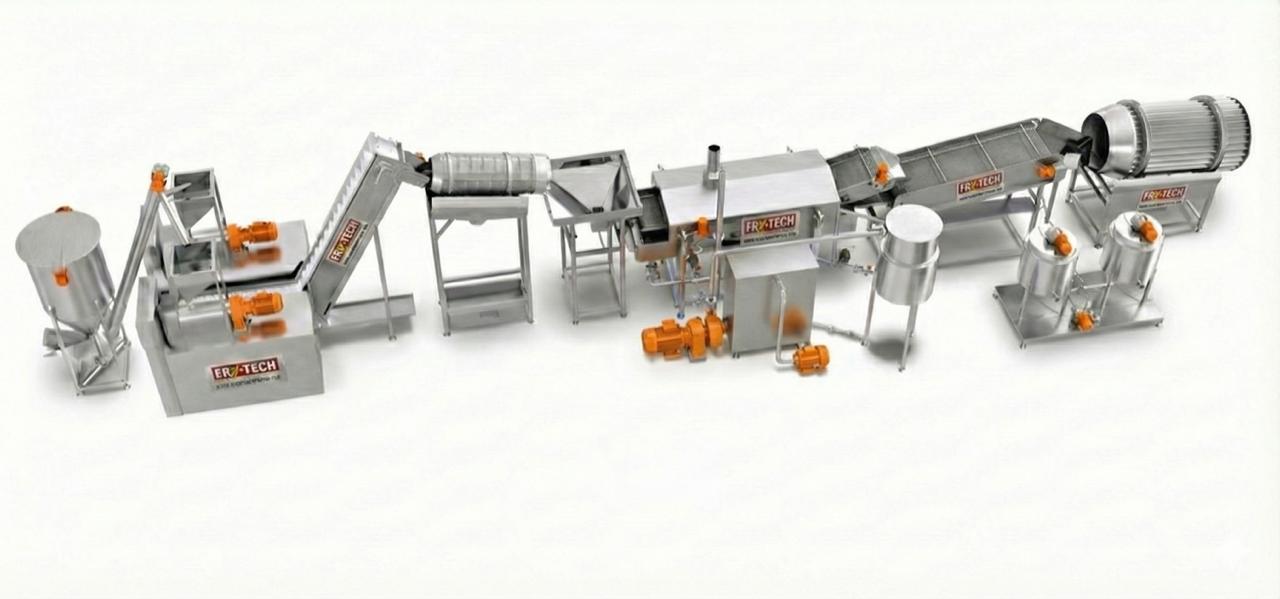

Fully Automaic Kurkure Production Line

A Fully Automatic

Kurkure (Nik Naks) Production Line for capacities of 100 to 400 kg/hour is a

sophisticated, end-to-end industrial system. At this scale, the line typically

relies on Rotary Head Extrusion technology to create the signature irregular,

crunchy shape of the snack.

Below are the

technical details, machine components, and space requirements for this range.

1. The Production

Flow (Step-by-Step)

- Mixing: Corn grits are moisturized and

blended with water in a Flour Mixer.

- Extrusion: The moisturized grits are fed

into the Rotary Head Extruder, where friction and pressure

"cook" and shape the curls.

- Separation: A Rotary Sifter removes small

"fines" or broken pieces to ensure oil stays clean during

frying.

- Frying: The curls move through a Continuous

Fryer to achieve a crisp texture.

- De-Oiling: Excess oil is removed via a Vibratory

De-oiler or belt.

- Flavoring: Snacks enter a Flavoring Drum

where seasoning is applied uniformly.

- Packaging: Finished product is moved to Automatic

VFFS (Pouch Packing) Machines.

2. Technical

Specifications by Capacity

|

Feature |

100 - 150 kg/hr

Line |

300 - 400 kg/hr

Line |

|

Main Extruder |

1 Unit (20-30 HP

Motor) |

2 or 3 Units

(working in parallel) |

|

Total Power Load |

~40 kW to 55 kW |

~75 kW to 95 kW |

|

Floor Space |

~1,000 to 1,500

Sq. Ft. |

~2,000 to 2,500

Sq. Ft. |

|

Line Length |

~40 to 50 Feet |

~70 to 80 Feet |

|

Oil Capacity |

150 - 200 Liters |

350 - 450 Liters |

|

Fuel for Fryer |

Diesel / Gas /

Wood Pellet |

Diesel / Gas /

Thermic Fluid |

3. Key Machine

Components in the Line

- Rotary Head Extruder: This is the heart of

the plant. High-quality models use Brass/Bronze Rotary Die Plates and

alloy steel screws for durability.

- Continuous Fryer: For 400 kg/hr, you need

a Multi-Zone Heat Control fryer. This ensures that the oil at the start of

the belt is hot enough to "puff" the Kurkure, while the end is

cool enough to prevent burning.

- Seasoning System: Includes a Slurry Tank

(if using liquid seasoning) and a Zig-Zag Flavoring Drum to ensure 100%

coverage without breaking the delicate curls.8

- Vibratory De-oiler: Critical for the

"400 kg/hr" line to prevent the final product from feeling

greasy and to save on oil costs.