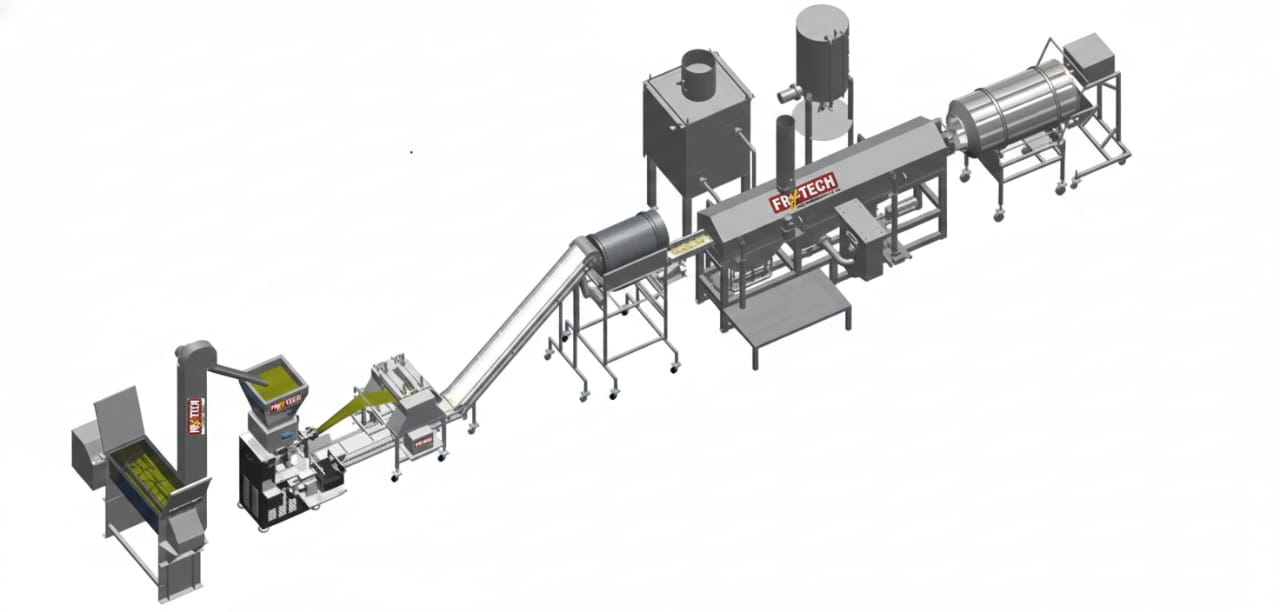

Fully Automatic Panipuri Fryer Machine

Fully Automatic Wheat-Based Snack Line, fully-automatic-panipuri-fryer-machine commonly used

for products like Pani Puri (Gol Gappa), wheat chips, or papad-style

snacks. Unlike potato chips, this line relies on dough rheology, sheeting, and

fermentation (proofing).

1. Raw Material Handling & Dough Preparation

- Raw

Wheat Flour Hopper & Elevator: Automatically transfers bulk flour

to the mixer to prevent manual lifting and dust contamination.

- Flour

Mixer (Blender Type):

- Mechanism:

Uses a horizontal screw (ribbon blender style) for intensive mixing of

flour, water, and additives.

- Dimensions:

700 Dia x 1500 Length. This volume is sized to provide a consistent

buffer for the sheeter.

2. Cutting & Sheeting Machine (The

"Forming" Stage)

This is the most critical part for texture and expansion.

- Multi-Stage

Rolling: The dough passes through six rollers. Gradual

reduction (from thick dough to 0.51.0mm is vital. If you reduce thickness

too quickly, the gluten network breaks, and the chips won't puff (expand)

during frying.

- Components:

* Stainless Steel (SS) Rollers: For hygiene and precision.

- Rubber/Teflon

Rollers: To prevent sticking.

- Teflon

Cutting Die: Custom-shaped rollers that "punch out" the

Pani Puri or chip shapes from the continuous sheet.

- Price

Note: ₹4,20,000/- reflects the complexity of the multi-roller

synchronization.

3. Proofer System (Fermentation)

- Function:

Specifically, for Pani Puri. The cut discs need to rest so the

yeast/enzymes can act and the moisture can equilibrate.

- Scale:

An 85-foot length is massive, designed to handle 1500kg of

dough. This ensures that even at high speeds, every chip gets the required

2 to 6 hours of "dwell time" before hitting the oil.

Without this, the snacks will be flat and hard rather than hollow and

crispy.

4. Continuous Belt Fryer (Working Principle)

This is a High-Spec Spray-Nozzle Fryer, which is

different from a simple dip fryer.

- Spray

Nozzle Principle: Instead of just dropping chips into a vat, hot oil

is sprayed or circulated gently over the product. This ensures that light

wheat chips don't clump together and that they expand uniformly.

- Zonal

Temperature Control: The modular design allows different

"cells."

- Zone

1: High heat for initial "pop" or expansion.

- Zone

2: Lower heat to cook the interior and remove moisture without

burning the surface.

- Versatility:

Can be heated via the 100kg Steam Boiler mentioned in your previous

requirement or via hot oil/gas.

5. Post-Frying: Inspection & Cooling

- Inspection

Conveyor: Allows for manual removal of "un-puffed" or broken

pieces.

- Cooling

Conveyor: Uses ambient air to bring the temperature down to room

level. This is crucial; if you pack wheat snacks while warm, they will

create condensation inside the bag and turn soggy within 24 hours.

Summary of Specifications

|

Component |

Power/Size |

Key Advantage |

|

Dough Mixer |

2.1kW |

Screw-type ensures no dry flour pockets. |

|

6-Stage Sheeter |

0.51.0mm |

Maximum expansion (puffing) ratio. |

|

Proofer |

85 Feet |

Massive capacity for continuous 24/7 operation. |

|

Belt Fryer |

Modular |

Independent temp control per section. |

Recommendations for your Setup:

- Scrap

Recycling: Ensure your cutting machine has a Scrap Return Conveyor.

Since you are cutting circles (Pani Puri) from a square sheet, you will

have 30% to 40% waste dough. A

fully automatic line should feed this back into the mixer.