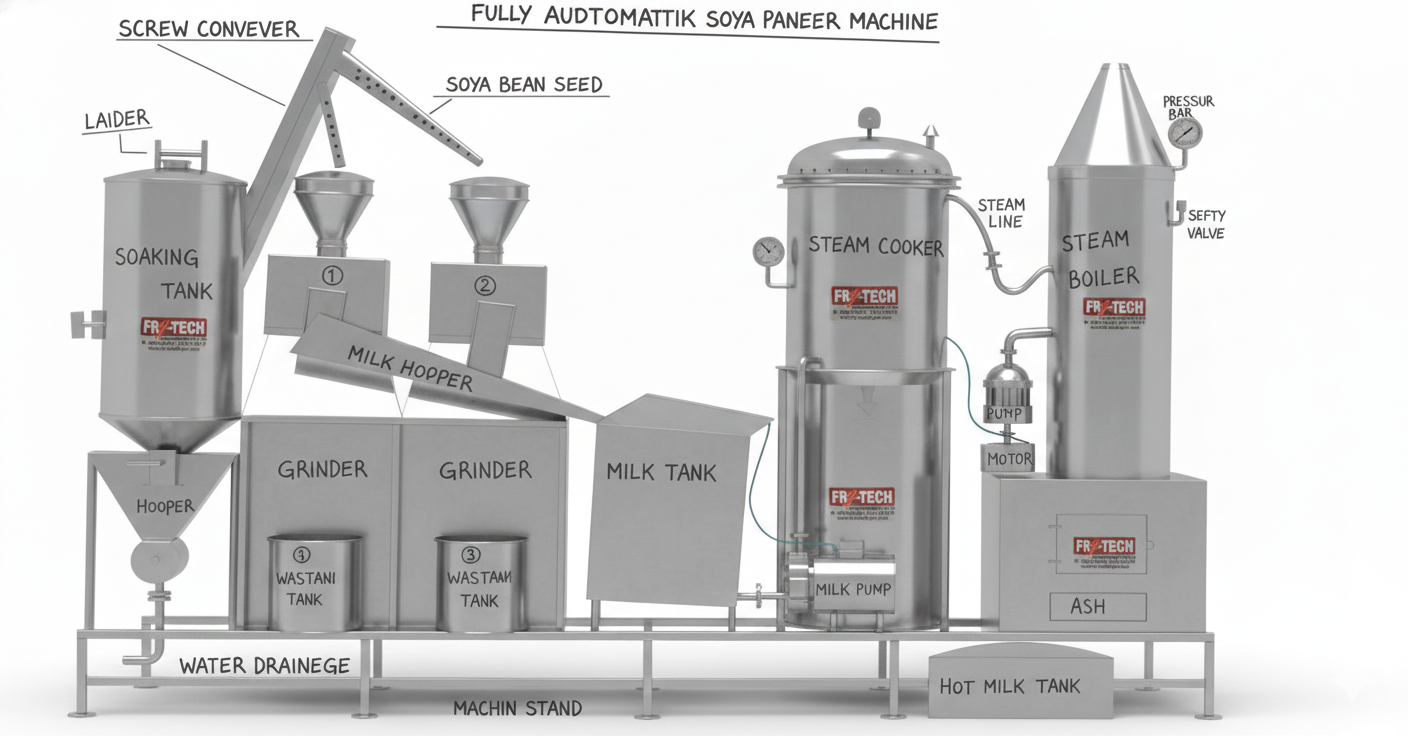

Tofu, Machine Fully Automatic Soya Paneer machine

Fully Automatic Soya Paneer (Tofu) Machine is a complete

"Integrated Production Line" that handles everything from the soaked

soybean to the final compressed block of paneer. For an industrial setup, the Steam

Heating system is preferred over electric heaters because it prevents the milk

from sticking or burning (no "beany" or burnt smell).

1. The Full Automated Process (Grinding to Press)

- Automatic

Grinding & Separation: Soaked beans are fed into the SS Grinder. The machine automatically separates the "Okara" (fiber/residue)

from the "Soya Milk" in one step.

- Vacuum/Steam

Cooking: The milk is pumped into a Steam Jacket Cooker. Steam is injected

at high pressure, which deactivates the enzymes (eliminating the raw bean

taste) and sterilizes the milk at 100 C

- Coagulation

(Ordering): The hot milk is moved to a mixing tank where a coagulant (like

GDL or Magnesium Chloride) is added to turn the milk into curds.

- Automatic

Pneumatic Press: The curds are poured into molds. A Pneumatic

(Air-Powered) Press then applies uniform pressure to squeeze out the whey,

forming perfect, firm blocks of Tofu.

2. Technical Specifications (Industrial 100–250 LPH)

|

Component |

Specification |

|

Material |

SS 304 Food Grade (Inner & Outer Body) |

|

Steam Boiler |

Electric, Gas, or Wood Pellet (Capacity: 2–5 kg/hr) |

|

Grinder Motor |

1 HP to 3 HP (High Speed 2800 RPM) |

|

Press Type |

Dual-Head Pneumatic Press (Requires 1 HP Compressor) |

|

Yield |

1 kg Soybeans = Approx. 2 kg to 2.5 kg Tofu |

|

Automation |

PLC Touch Screen for Temperature and Timer control |

Why Steam Heating

is Essential

If you use direct

electric coils, the protein in the soya milk sticks to the coil and burns,

creating black spots in your tofu. Steam Heating (using a

double-jacketed vessel) provides "indirect heat," ensuring your tofu

stays pure white and has a silky texture with no burnt

aftertaste.