Fully Automatic Potato Chips Line

FRY-TECH fully automatic potato chips production line is an integrated "farm-to-bag" system designed to process raw potatoes into packaged snacks with minimal human intervention. To operate a high-capacity line (e.g., 300 kg/hr to 1,000 kg/hr), the machinery must be synchronized via a central PLC (Programmable Logic Controller) system.

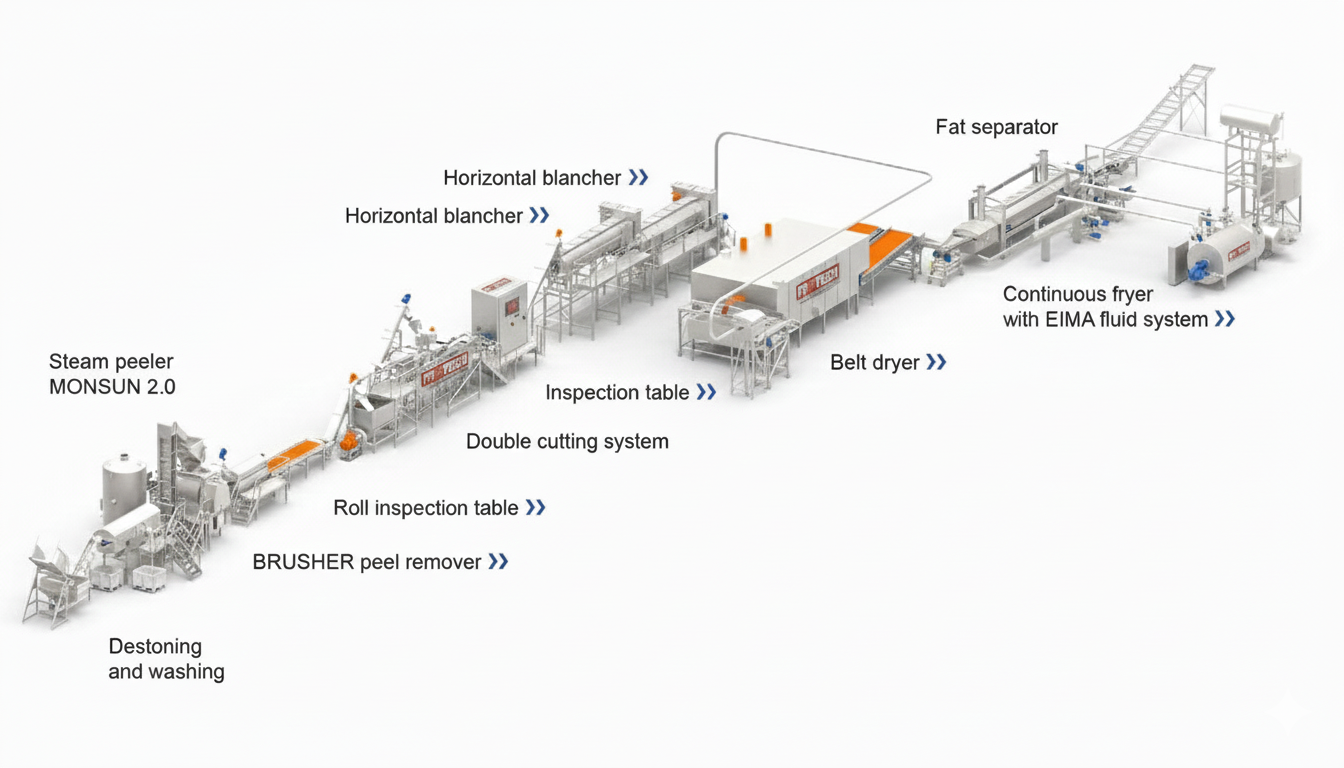

1. The Production Workflow

The line follows a sequential process, ensuring that every chip is uniform in thickness, colour, and flavour.

Stage A: Raw Preparation

- Potato

Grader: A drum or roller-type machine that sorts potatoes by size to

ensure consistent peeling and slicing.

- De-Stoner:

A water-filled hopper with a vertical screw. Gravity pulls stones to the

bottom while potatoes float and move upward.

- Continuous

Peeler: Uses abrasive carborundum rollers to rub off the skin. A

"Sine Wave" design prevents the potatoes from flat-spotting.

- Inspection

Belt: A roller conveyor that tumbles the peeled potatoes so operators can

manually remove any remaining "eyes" or defects.

Stage B: Slicing & Pre-Treatment

- Slicer:

High-speed centrifugal slicers cut potatoes into plain or ruffled slices

(typically 1.2mm to 1.5mm thick).

- Blancher:

A hot water bath (70°C–90°C) that removes surface starch and inhibits

enzymes. This prevents the chips from turning dark brown during frying.

- Belt

Dryer (Air Knife System): Uses high-velocity fans and air

"knives" to strip surface moisture. Removing this water is

critical to saving oil and reducing frying time.

Stage C: Frying & Sorting

- High-Speed

Conveyor: Transfers dried slices into the fryer in a thin, even layer.

- Continuous

Fryer: The "heart" of the line. It features an internal heat

exchanger, a dual-belt submerge (to keep chips underwater), and a

continuous oil filtration system that removes "fines" (starch

particles) every minute.

- Cooling

Conveyor: Fried chips travel over a mesh belt with ambient air fans to

drop the temperature before seasoning.

- Colour

Sorting Conveyor: An optical sorter uses high-speed cameras to detect and

"air-blast" out any burnt or discoloured chips.

Stage D: Flavouring & Packaging

- Flavouring

Sprayer & Drum: A liquid oil sprayer first mists the chips, followed

by a dry powder applicator. The rotating "Zig-Zag"

drum ensures 360-degree coverage without breaking the chips.20

- Multi-Head

Packing Machine: A 10 or 14-head weigher accurately measures the weight

(e.g., 30g) and drops them into the bagger, which flushes the bag with Nitrogen

for shelf-life before sealing.21

2. Technical Requirements (300 kg/hr Line)

Specification

Requirement

Power Consumption

Approx. 65 HP to 75 HP

Water Consumption

2,000 to 3,000 Liters / Hour (Recirculated)

Floor Space

Minimum 3,000 to 4,000 Sq. Ft.

Fuel (Fryer)

Wood or Natural Gas

Material

All contact parts AISI 304 Stainless Steel

Electroporation (PEF): New lines are replacing blanchers with Pulse Electric Field (PEF) systems. This uses electricity to open potato cells, resulting in a crunchier chip with 10% less oil absorption.

Smart Oil Management: Systems now monitor the Acid Value of oil in real-time, automatically adding fresh oil to keep the "turnover ratio" high and the quality consistent.

AI Sorting: Colour sorters now use AI to distinguish between "green" potato edges and "burnt" spots, reducing waste of perfectly good chips.

- Potato

Grader: A drum or roller-type machine that sorts potatoes by size to

ensure consistent peeling and slicing.