Onian Powder Machine Belt Dryer

500 kg per hour of

finished onion powder, you are looking at a massive industrial operation.

Because onions have a very high water content (approx. 85–90%), the conversion

ratio is typically 9:1.1

This means to get

500 kg of powder, your "Front-End" machines must be capable of

processing 4,500 kg to 5,000 kg of raw onions every hour.

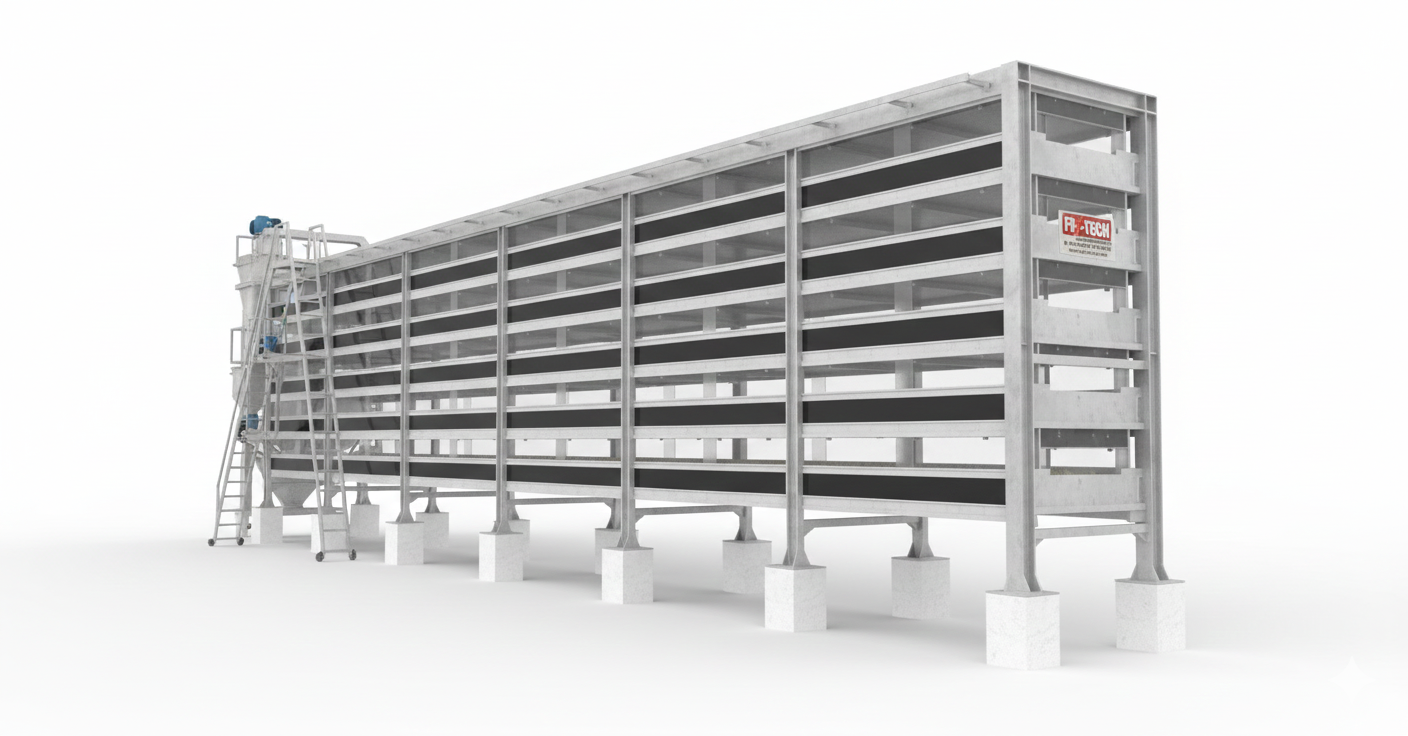

1. The Belt Dryer

(The Heart of the System)

For this capacity,

a Multi-Layer Stainless Steel Mesh Belt Dryer is mandatory. It allows for

continuous dehydration without the labor of manual tray loading.

|

Feature |

Details for 500

kg/hr Finished Output |

|

Type |

3-Layer or

5-Layer Continuous Mesh Belt Dryer |

|

Belt Width |

2000 mm (2

Meters) |

|

Drying Length |

10 to 15 Meters

(Effective drying area approx. 60–80 $m^2$) |

|

Temperature |

60°C to 80°C (Low

temperature prevents browning) |

|

Heat Source |

Steam (Boiler),

Natural Gas, or Heat Pump |

|

Drying Time |

3 to 5 hours

(total transit time) |

|

Material |

All contact parts

SS 304; Food-grade Teflon/SS mesh belt |

2. Complete

Production Line Flow

A fully automatic

500 kg/hr line involves these specific machines in sequence:

A. Pre-Processing

(Handling ~5 Tons/hr Raw)

- Onion Peeler & Root Cutter:

High-capacity pneumatic peelers that remove skin using air pressure to

avoid damaging the bulb.2

- Bubble Washing Machine: Uses high-pressure

water bubbles and a spray system to remove mud and loose skins.

- Onion Slicer: Slices onions into uniform 2mm

to 4mm thicknesses.3 Uniformity is critical; if slices vary,

some will burn while others remain wet.

B. Dehydration (The

Belt Dryer)

- Feeding Conveyor: Spreads the slices

evenly across the width of the belt.4

- Multi-Layer Belt Dryer: Slices travel on

the top belt, drop to the middle, and then the bottom. This

"flipping" ensures even drying on both sides.

- De-humidification System: High-velocity

fans extract moist air continuously to prevent the onions from

"stewing" in their own steam.

C. Post-Processing

(Powder Making)

- Impact Pulverizer / Grinder: Dried flakes

are extremely hygroscopic (absorb moisture).5 They are ground

into 60–100 mesh powder in a temperature-controlled environment.

- Vibro Sifter: Separates the fine powder

from any unground granules.

- Automatic Vacuum Packaging: Onion powder

must be packed immediately into moisture-proof bags/bottles, or it will

turn into a hard lump within minutes.

3. Technical &

Utility Requirements

- Power Load: Approximately 80 kW to 120 kW

(for motors, blowers, and conveyors).

- Space Required: A linear space of at least

80 to 100 feet in length.

- Fuel Consumption: * If Steam: ~800 kg to

1000 kg/hr steam.

- If Gas: ~40 to 60 kg/hr LPG.

4. Critical Quality

Tip: "The Color Secret"

To get the

"Bright White" or "Golden Yellow" powder seen in export

markets, many industrial lines include a Blanching Unit before the dryer. This

deactivates the enzymes that cause the onion to turn brown or grey during the

4-hour drying process.