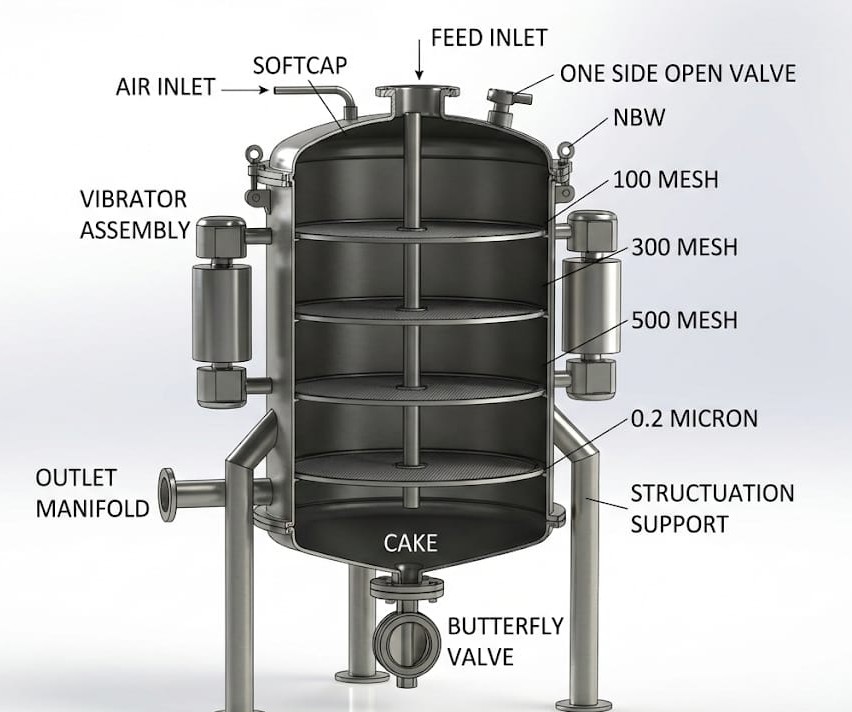

Vaccum Edible Oil Filter Machine

The Four-Stage Filtration Design

To meet your requirements, the machine should be designed with the

following gradient:

|

Stage |

Filter Type |

Purpose |

|

Stage 1 |

100 Mesh (150 Micron) |

Removes large "fines," crumbs, and burnt

particles. |

|

Stage 2 |

300 Mesh (50 Micron) |

Removes medium-sized sediment and flour particles. |

|

Stage 3 |

500 Mesh (25 Micron) |

Removes very fine dust and carbonized particles. |

|

Stage 4 |

0.02 Micron Membrane |

Ultra-Filtration: Removes bacteria, colloidal

particles, and microscopic impurities to make the oil crystal clear. |

2. Technical Details for 35 L/min

Flow

Filtering 500 liters in 15 minutes the machine have a :

- High-Pressure

Vacuum Pump: A powerful vacuum (usually Water Ring or Rotary Vane type) to

"pull" the thick oil through the 0.02-micron membrane.

- Multi-Cartridge

Housing: housing containing multiple 20-inch or 30-inch cartridges to

provide enough surface area for the 100 L/min flow.

- Intermediate

Buffer Tank: To prevent the pump from cavitating, a small buffer tank is

needed between stages.

- Edible oil must

be temperature on 120 degree plus

- Suction By high-pressure pump (Gear Pump or Screw

Pump) rather than just a vacuum.